Email: gm@indianbarcode.com / newdelhiprintersdwarka@gmail.com

Phone: +91-9717122688 / +91-9810822688

Email: gm@indianbarcode.com / newdelhiprintersdwarka@gmail.com

Phone: +91-9717122688 / +91-9810822688

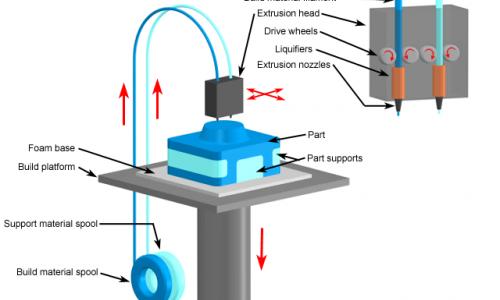

Fused Deposition Modeling (FDM) was developed by Stratasys in Eden Prairie, Minnesota. In this process, a plastic or wax material is extruded through a nozzle that traces the part's cross sectional geometry layer by layer. The build material is usually supplied in filament form, but some setups utilize plastic pellets fed from a hopper instead. The nozzle contains resistive heaters that keep the plastic at a temperature just above its melting point so that it flows easily through the nozzle and forms the layer. The plastic hardens immediately after flowing from the nozzle and bonds to the layer below. Once a layer is built, the platform lowers, and the extrusion nozzle deposits another layer. The layer thickness and vertical dimensional accuracy is determined by the extruder die diameter, which ranges from 0.013 to 0.005 inches. In the X-Y plane, 0.001 inch resolution is achievable. A range of materials are available including ABS, polyamide, polycarbonate, polyethylene, polypropylene, and investment casting wax.

Mindware is Asia’s largest provider of Fused Deposition Modelling

Printing Solutions. New Delhi Printers being the brainchild of Mindware, thus

inculcating all the expertise into its products and services, provides best solutions

for Fused Deposition Modelling Printing Solutions.

Best Fused Deposition Modelling Printing Solutions call

+91 9810822688 and mail us at gm@indianbarcode.com

|

Abbreviation: |

FDM |

|

Material

type: |

Solid

(Filaments) |

|

Materials: |

Thermoplastics

such as ABS, Polycarbonate, and Polyphenylsulfone; Elastomers |

|

Max part

size: |

36.00 x 24.00

x 36.00 in. |

|

Min

feature size: |

0.005 in. |

|

Min layer

thickness: |

0.0050 in. |

|

Tolerance: |

0.0050 in. |

|

Applications: |

Form/fit testing,

Functional testing, Rapid tooling patterns, Small detailed parts,

Presentation models, Patient and food applications, High heat applications |