Email: gm@indianbarcode.com / newdelhiprintersdwarka@gmail.com

Phone: +91-9717122688 / +91-9810822688

Email: gm@indianbarcode.com / newdelhiprintersdwarka@gmail.com

Phone: +91-9717122688 / +91-9810822688

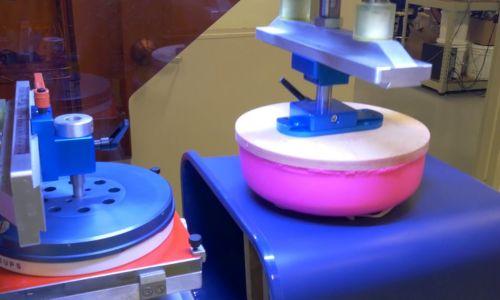

Pad printing is a versatile printing technique known for its ability to conform to uneven surfaces. Unlike traditional flatbed printing, pad printing utilizes a silicone pad to transfer an image. The process involves an etched plate with the desired design, an ink reservoir, and the silicone pad itself. Ink is flooded onto the plate, and a doctor blade scrapes away excess ink, leaving it only in the etched areas. The silicone pad then presses down onto the plate, picking up the ink design. Finally, the pad presses onto the product, conforming to its shape and leaving a crisp, detailed image. Pad printing is ideal for decorating curved objects, like pens or mugs, and intricate shapes like buttons or keychains. It also offers the advantage of working with a wide range of materials, from plastic and metal to fabric and glass.

Best price for Pad Printing

call +91 9810822688 and mail us at gm@indianbarcode.com