Email: gm@indianbarcode.com / newdelhiprintersdwarka@gmail.com

Phone: +91-9717122688 / +91-9810822688

Email: gm@indianbarcode.com / newdelhiprintersdwarka@gmail.com

Phone: +91-9717122688 / +91-9810822688

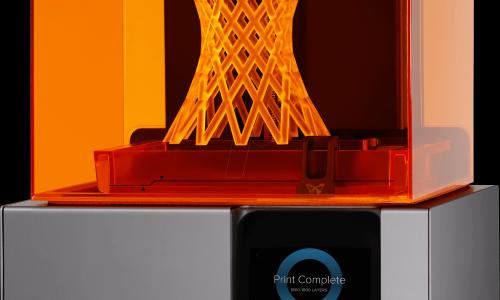

Stereolithography (SLA or SL; also known as stereolithography apparatus, optical fabrication, photo-solidification, or resin printing) is a form of 3D Printing technology used for creating models, Prototypes, Patterns, and production of parts in a layer by layer fashion using Photopolymerization, a process by which light causes chains of molecules to link, forming polymers. Those polymers then make up the body of a three-dimensional solid.

Mindware is Asia’s largest provider of SLA 3D Printing

Solutions. New Delhi Printers being the brainchild of Mindware, thus inculcating

all the expertise into its products and services, provides best solutions for SLA

3D Printing Solutions.

Best SLA 3D Printing Solutions call +91 9810822688 and

mail us at gm@indianbarcode.com